Surgical Drill Bits Specification, Uses, Sizes and Surgical Techniques.

During orthopedic surgery, surgical drill bits are used to create holes in the bone so that bone plates can be fixed with screws. It is possible to drill holes directly into bone without using a plate in order to place screws directly into the bone.

Surgical drills require fewer steps to simulate surgery, saving time by using a more reliable and accurate method. The availability of cutting-edge surgical drill bits allows for precise measurement from the outer skin layer to the end of the drill sleeve, which can be judged directly from the drill bit.

Our Drill Bits are made from high quality surgical stainless steel. These drill bits are rust proof, can used multiple times after sterilization.

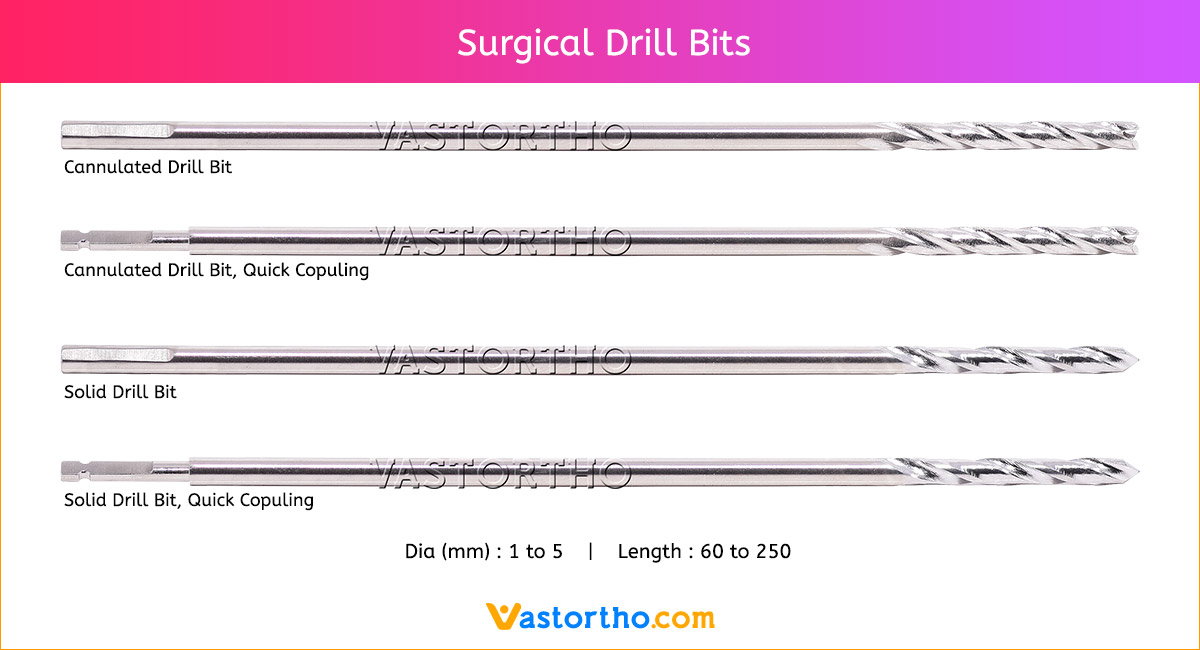

Surgical Drill Bits are available in various types, lengths and diameters.

Types: Solid Plain Shank, Solid Quick Copuling, Cannulated Plain Shank, Cannulated Quick Copuling

Diameters: 1 mm, to 5 mm

Lengths: 60 mm to 250 mm