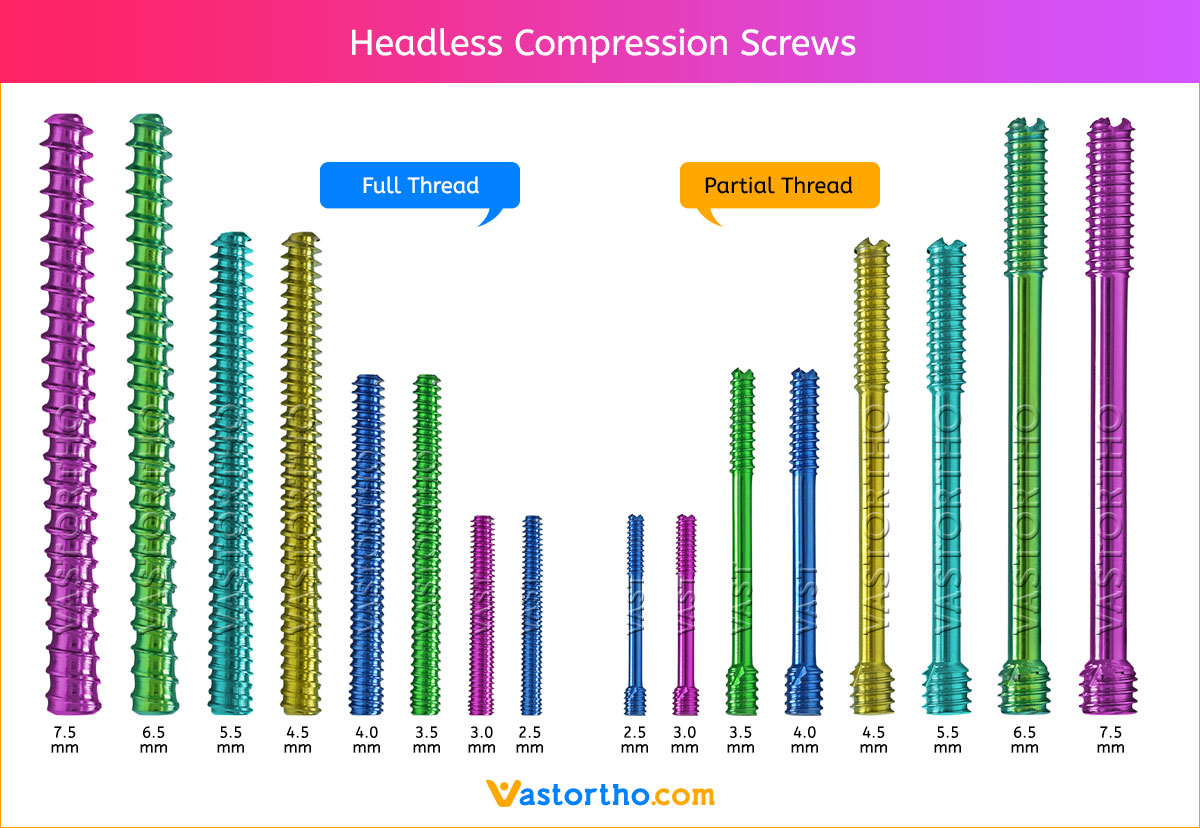

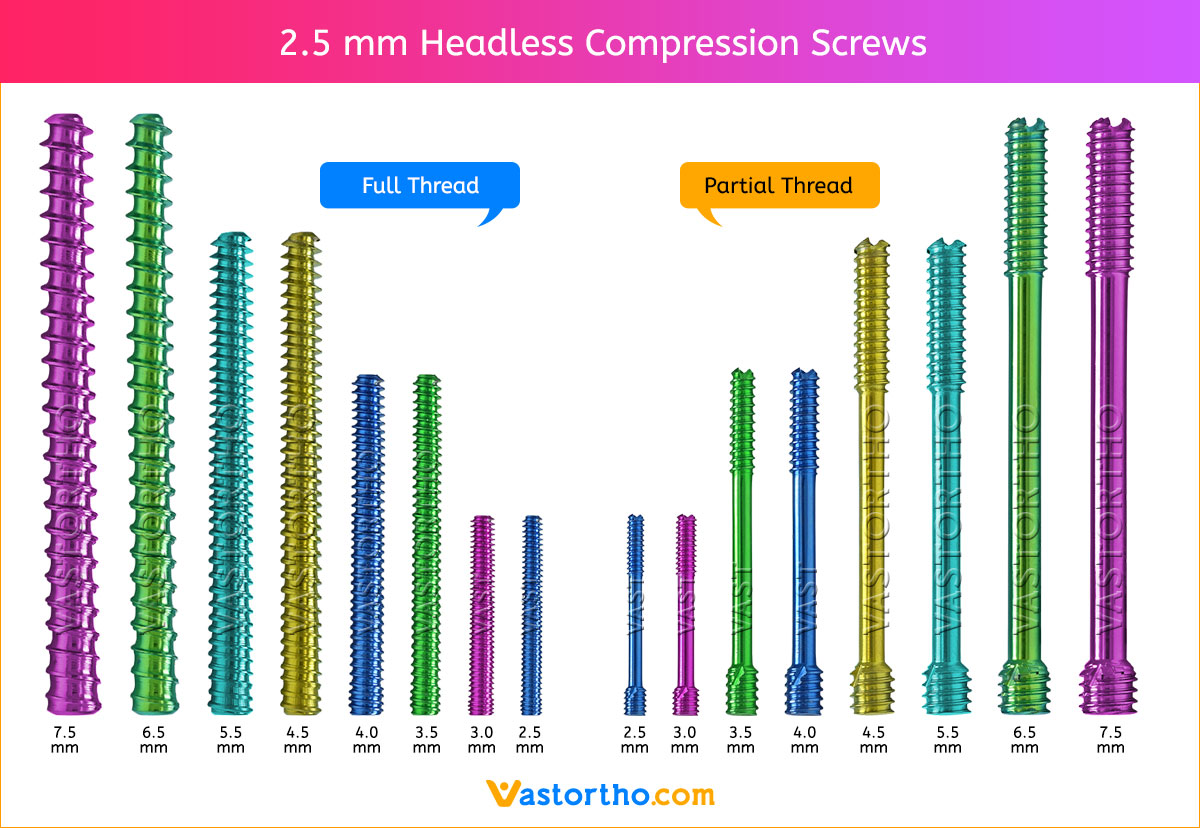

2.5 mm Screws Length

8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm and 30mm.

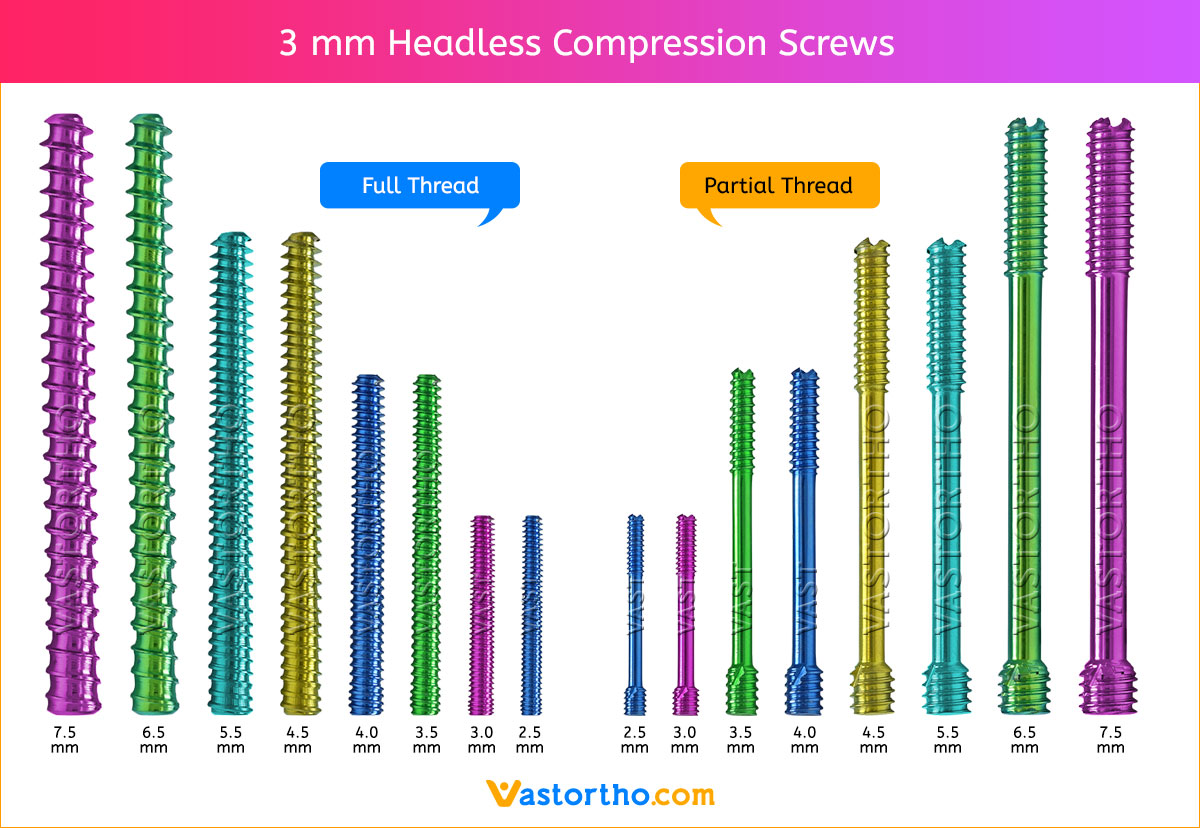

3 mm Screws Length

8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm and 30mm.

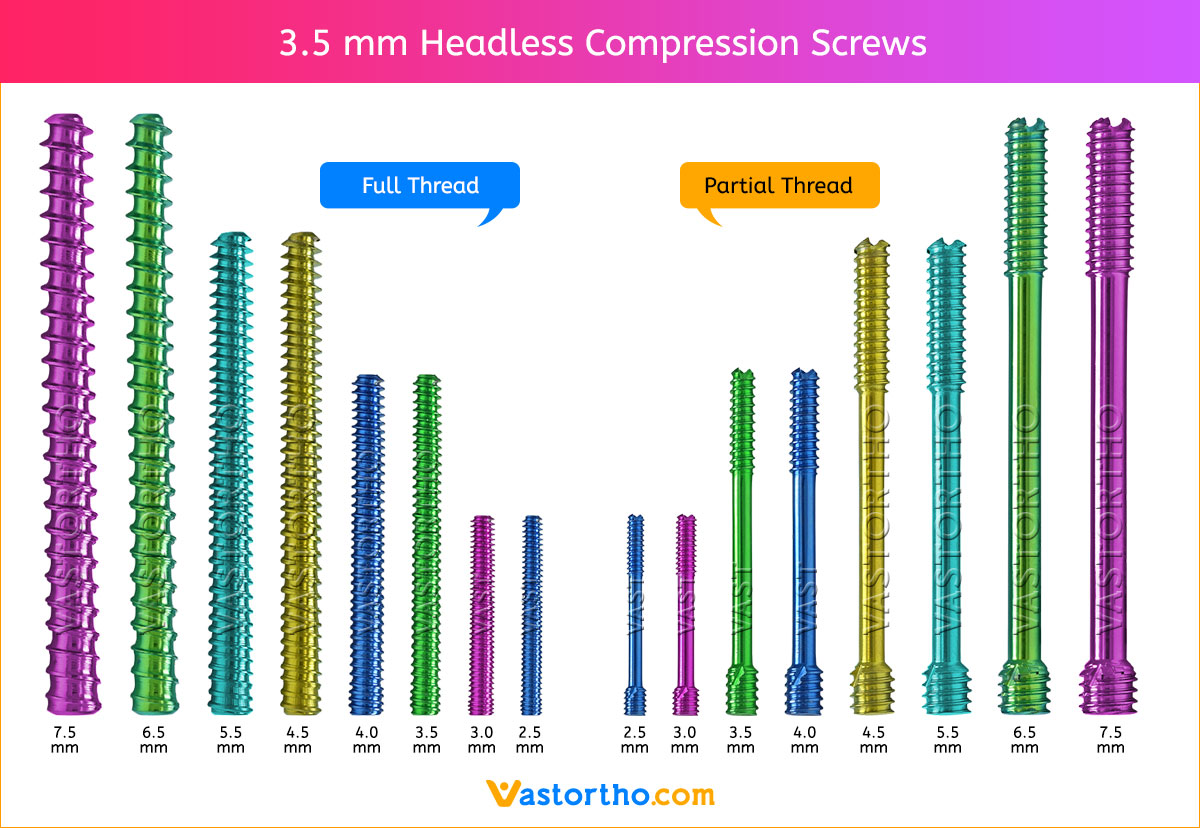

3.5 mm Screws Length

8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm and 80mm.

4 mm Screws Length

8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm and 80mm.

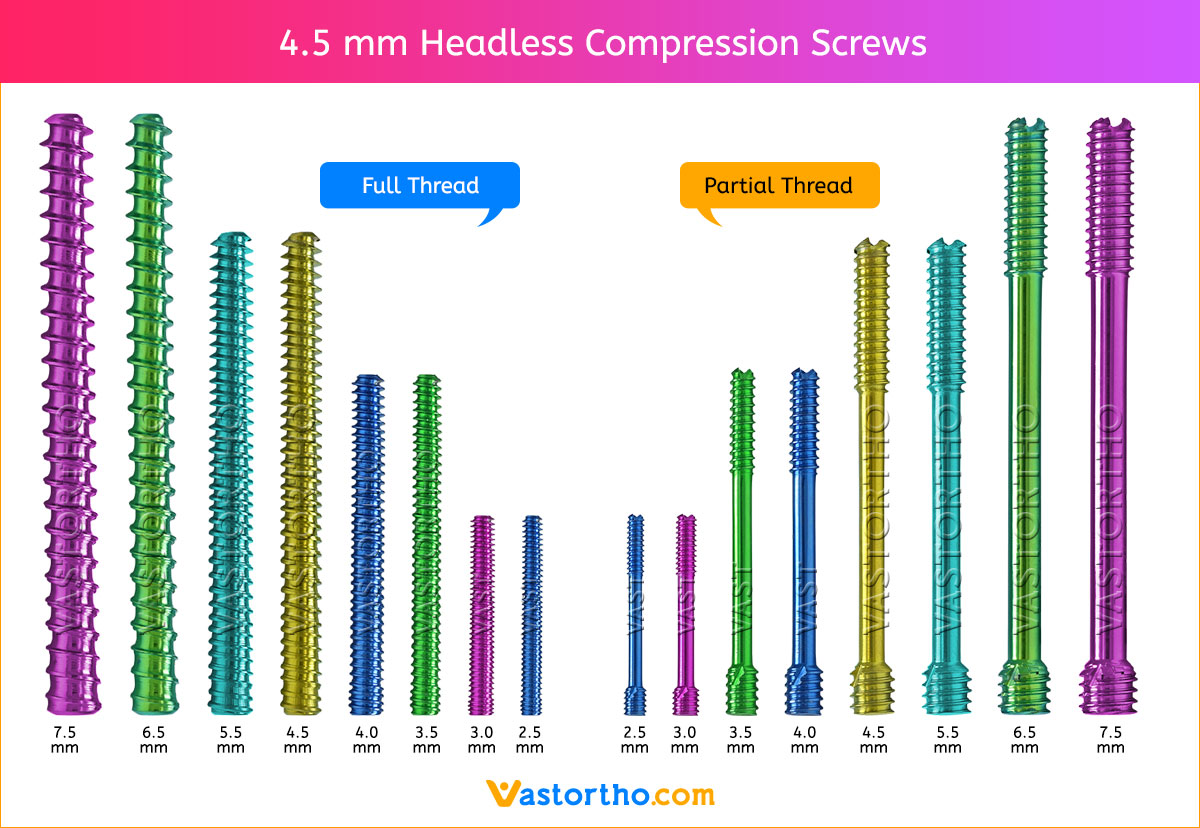

4.5 mm Screws Length

8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm and 80mm.

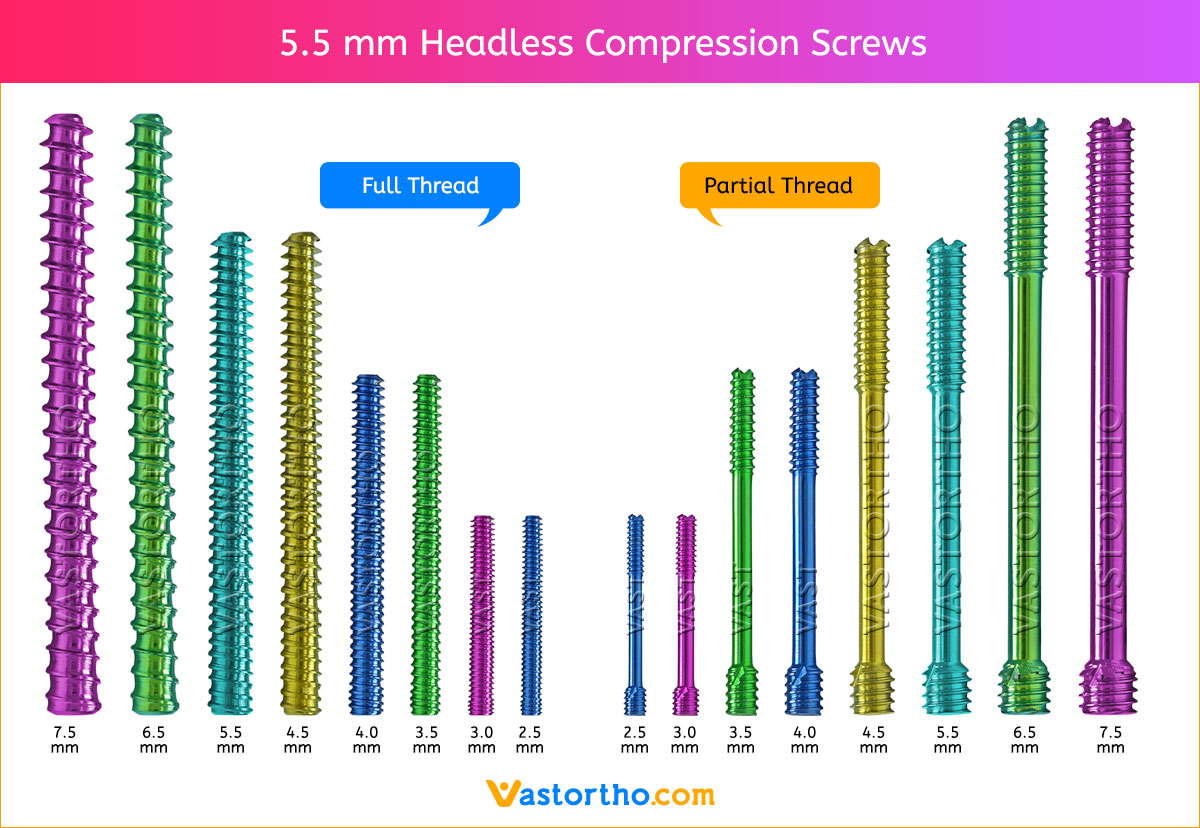

5.5 mm Screws Length

12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, 85mm, 90mm, 95mm, 100mm, 105mm, 110mm, 115mm and 120mm.

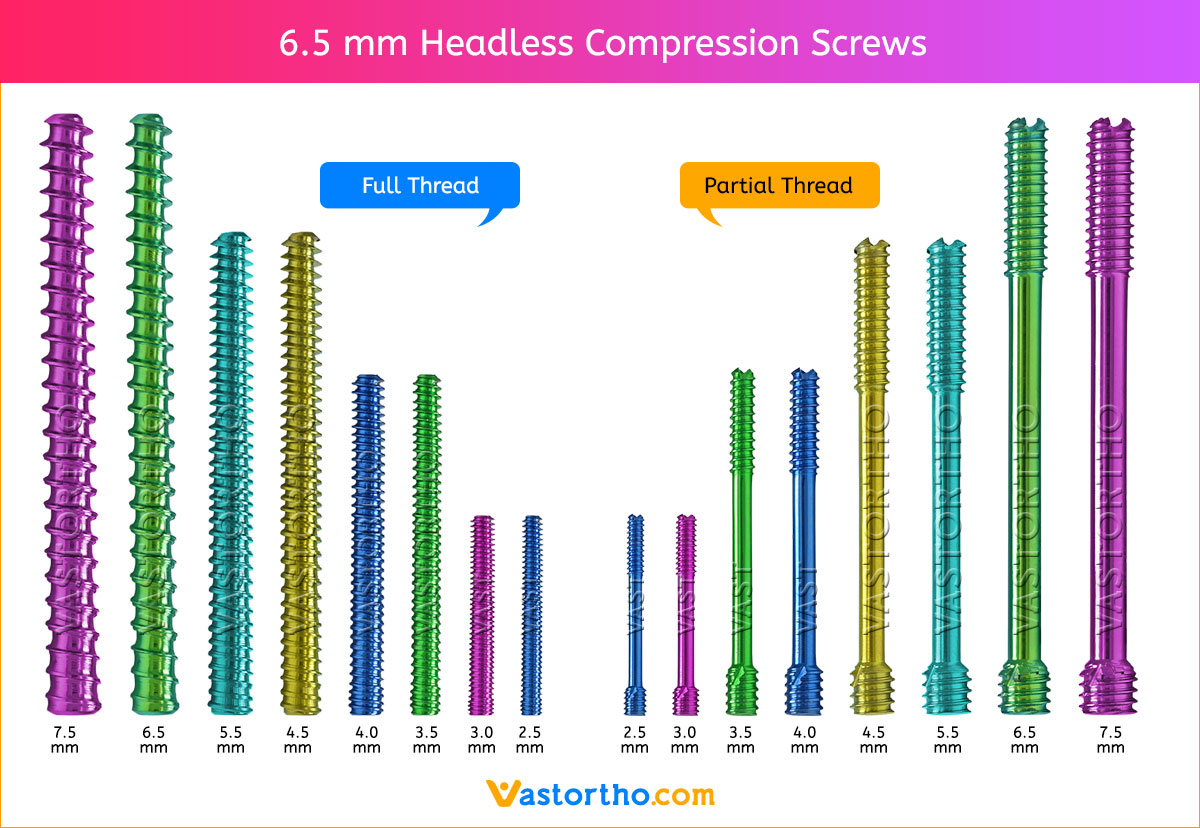

6.5 mm Screws Length

12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, 85mm, 90mm, 95mm, 100mm, 105mm, 110mm, 115mm and 120mm.

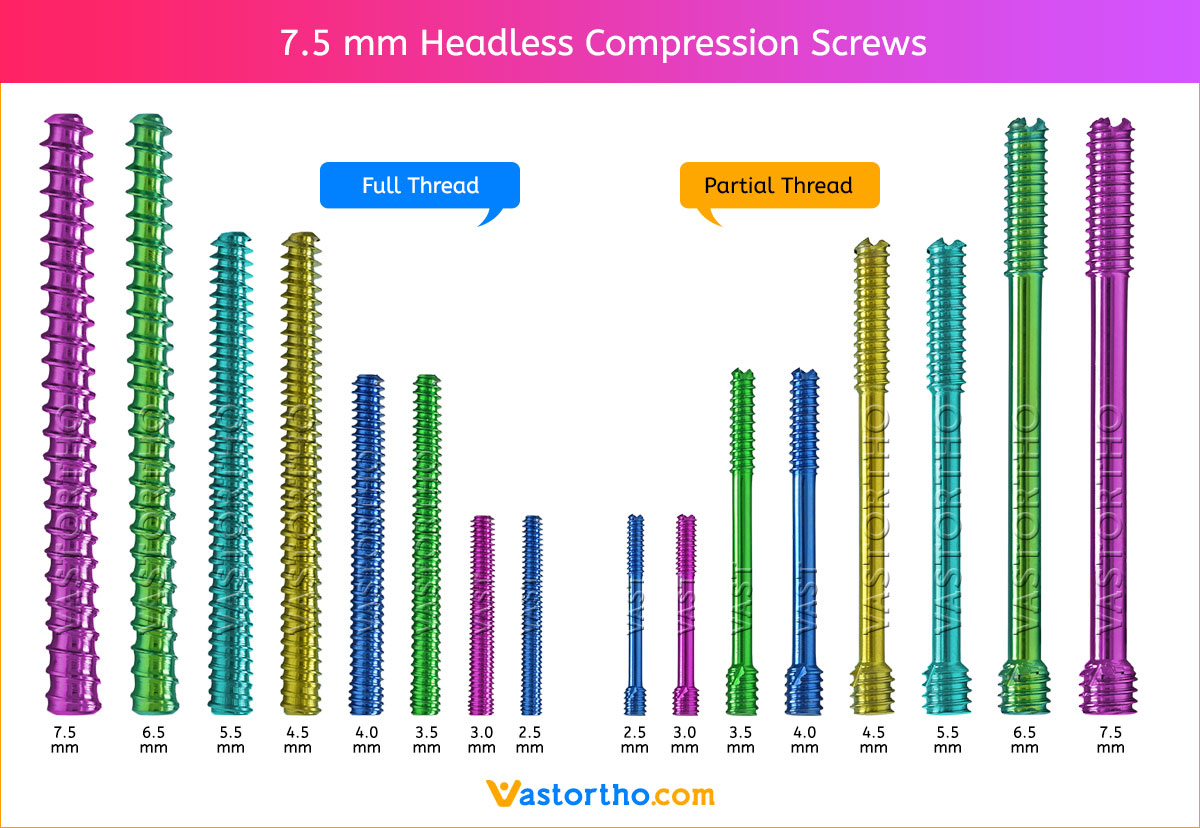

7.5 mm Screws Length

12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, 85mm, 90mm, 95mm, 100mm, 105mm, 110mm, 115mm and 120mm.

https://www.vastortho.com/wp-content/uploads/2.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-27 13:09:322023-07-22 12:57:592.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/2.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-27 13:09:322023-07-22 12:57:592.5 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/3-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-27 13:07:552023-07-22 13:00:153 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/3-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-27 13:07:552023-07-22 13:00:153 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/3.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-26 17:44:092023-07-22 13:01:483.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/3.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-26 17:44:092023-07-22 13:01:483.5 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/4-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-25 17:54:302023-07-22 17:10:034 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/4-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-25 17:54:302023-07-22 17:10:034 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/4.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-25 17:50:132023-07-22 17:15:494.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/4.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-25 17:50:132023-07-22 17:15:494.5 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/5.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-23 23:51:542023-07-22 17:17:575.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/5.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-23 23:51:542023-07-22 17:17:575.5 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/6.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-18 17:19:472023-07-22 17:22:526.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/6.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-18 17:19:472023-07-22 17:22:526.5 mm Headless Compression Screw https://www.vastortho.com/wp-content/uploads/7.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-17 12:01:172023-07-22 17:26:357.5 mm Headless Compression Screw

https://www.vastortho.com/wp-content/uploads/7.5-mm-Headless-Compression-Screws.jpg

828

1200

VastOrtho

https://www.vastortho.com/wp-content/uploads/Vast-Ortho-Logo-for-website.png

VastOrtho2018-08-17 12:01:172023-07-22 17:26:357.5 mm Headless Compression Screw