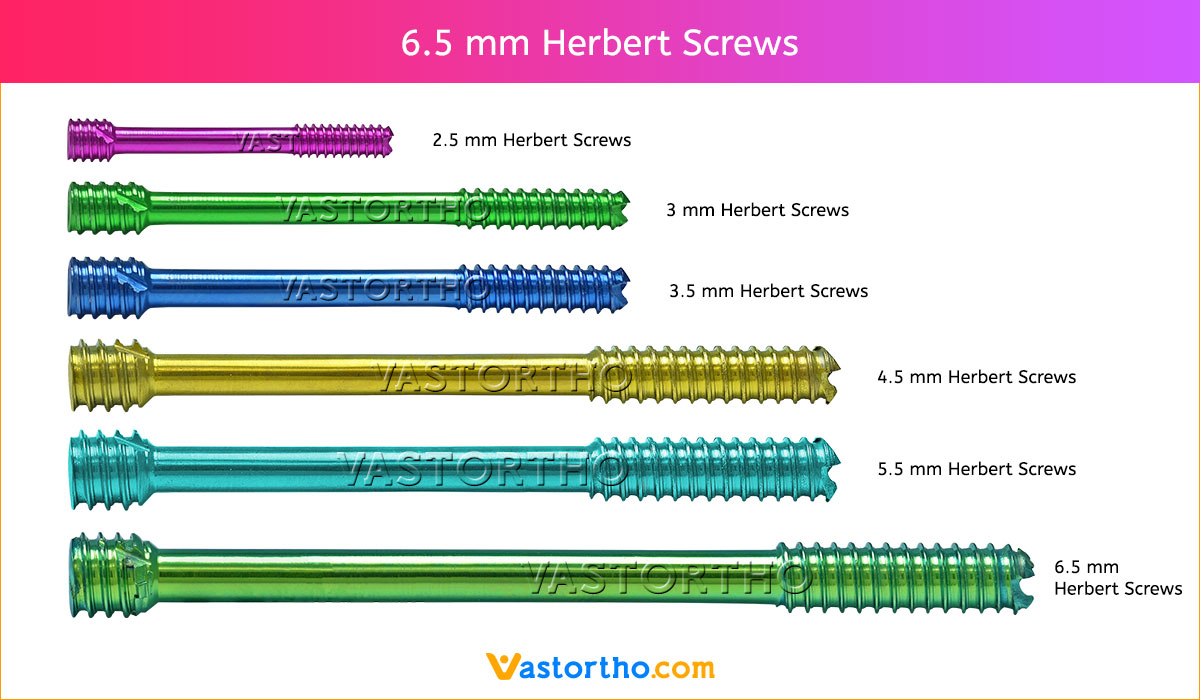

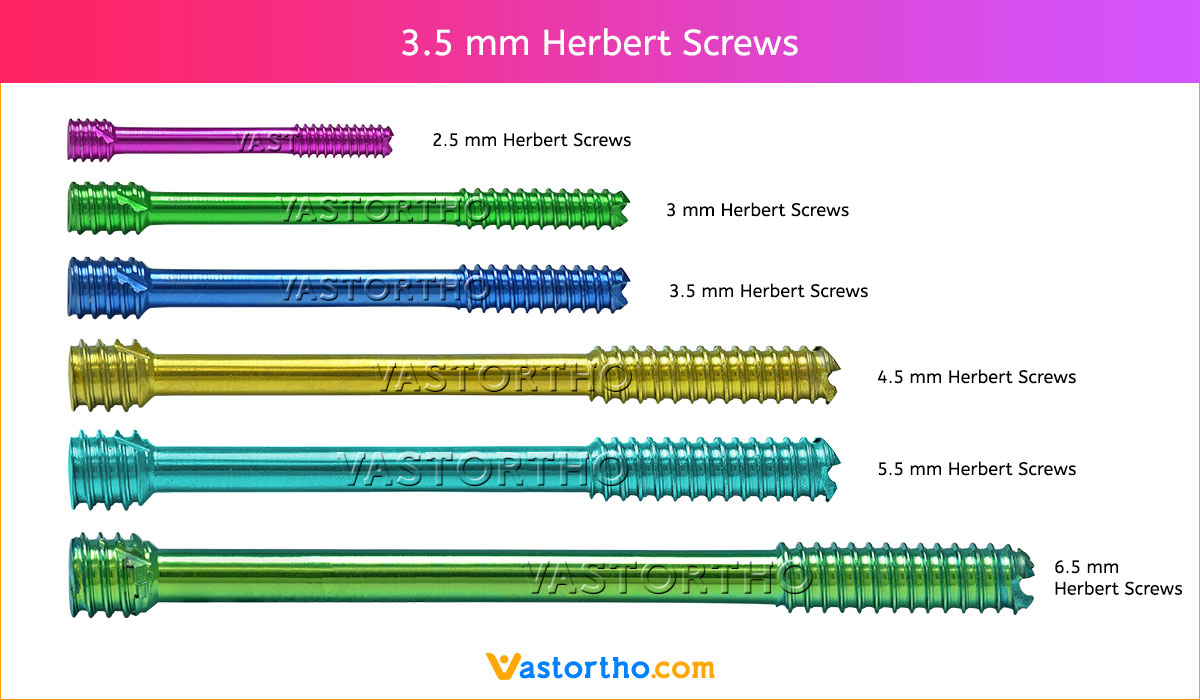

3.5 mm Herbert Screw Specification, Uses & Sizes

3.5 mm Herbert Screw Specification

- Herbert Screw has headless design, it means that the screw is completely embedded in the bone, without any protrusions to cause tissue irritation even in intra-articular placement.

- Cannulation helps ensure precise placement of the screw.

- The thread design of the Herbert Screw creates compression and provides fracture stability. As the proximal threads engage the bone, the fracture is drawn together, helping to create and maintain stability of the fracture site.

- Herbert Cannulated Guide Pins hold the fragment and act as guides for drilling, tapping, and screw placement.

- 3.5 mm Herbert Screws available lengths are 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 42mm, 44mm, 46mm, 48mm, 50mm, 55mm, 60mm, 65mm, 70mm, 75mm and 80mm.

- 3.5 mm Herbert Screw is made from pure Titanium and SS 316L.

- Any additional length sizes of this screw will be made on demand.

- Instruments are available for this screw such as Bone Taps, Combined Drill & Tap Sleeve, Counter Sink, Depth Gauge, Drill Bits, Drill Guide, Drill Sleeve, Hollow Mill Screw Removal, Reverse Measuring Device, Screw Drivers and Screw Holding Forceps etc.

3.5 mm Herbert Screw uses

Herbert Screw is designed for the management of fractures where minimal tissue coverage makes standard screw use inappropriate or where

extreme precision in fragment alignment is imperative. Such locations might include fractures of the:

Olecranon and malleolar region

Distal femur

Proximal tibia

Distal tibia

3.5 mm Herbert Screw is intended for fixation of intra-articular and extra-articular fractures and nonunions of small bones and small bone fragments; arthrodeses of small joint; bunionectomies and osteotomies, including scaphoid and other carpal bones, metacarpals, tarsals, metatarsals, patella, ulnar styloid, capitellum, radial head and radial styliod.