Insert guide wires

Fix condylar fragments with 6.5 mm cancellous lag screws, avoiding the planned insertion site of the blade. Bend the knee to 90° and mark the joint axis with the first Kirschner wire. Insert the second K-wire anteriorly over the patellofemoral surface of the condyles to mark the inclination. Mark the entry slot for the plate. Insert a third K-wire distal to the slot. This third wire must be parallel to the first wire in the AP view and to the second wire in the axial view. Check position with C-arm. Remove wires. The third wire indicates the direction of insertion of the seating chisel. Check the position with the condylar plate guide.

Insert chisel

In dense bone, predrill the channel with a 4.5 mm drill bit. Bevel the proximal rim with the chisel to avoid shattering of the cortex and to improve seating of the plate. Set the chisel guide at 85°, to result in 95° placement of the plate. Hammer the seating chisel in parallel to the K-wire in both planes. Check that the flap of the chisel guide is in line with the femoral shaft axis. Control rotation with the slotted hammer. After reaching the desired depth, take off the chisel guide and remove the seating chisel with the slotted hammer.

Insert plate

Fix the selected plate in the inserter -extractor, ensuring the blade is horizontally aligned with the handle, and tighten the bolt with the open-end wrench. Push the plate into the prepared channel and insert with light hammer blows. Control rotation with the slotted hammer. Remove the inserter-extractor, and use the impactor for final seating of the plate.

Secure plate to distal fragment

Predrill with a 3.2 mm drill bit through the round hole nearest the blade. In dense bone, the near cortex may have to be drilled with a 4.5 mm drill bit, to accept the screwshaft without cracking. Insert the appropriate length 6.5 mm partially threaded cancellous bone screw (to seat the plate and secure the medial fragment). Repeat the steps to insert a second 6.5 mm screw through the second round plate hole.

Secure plate to shaft

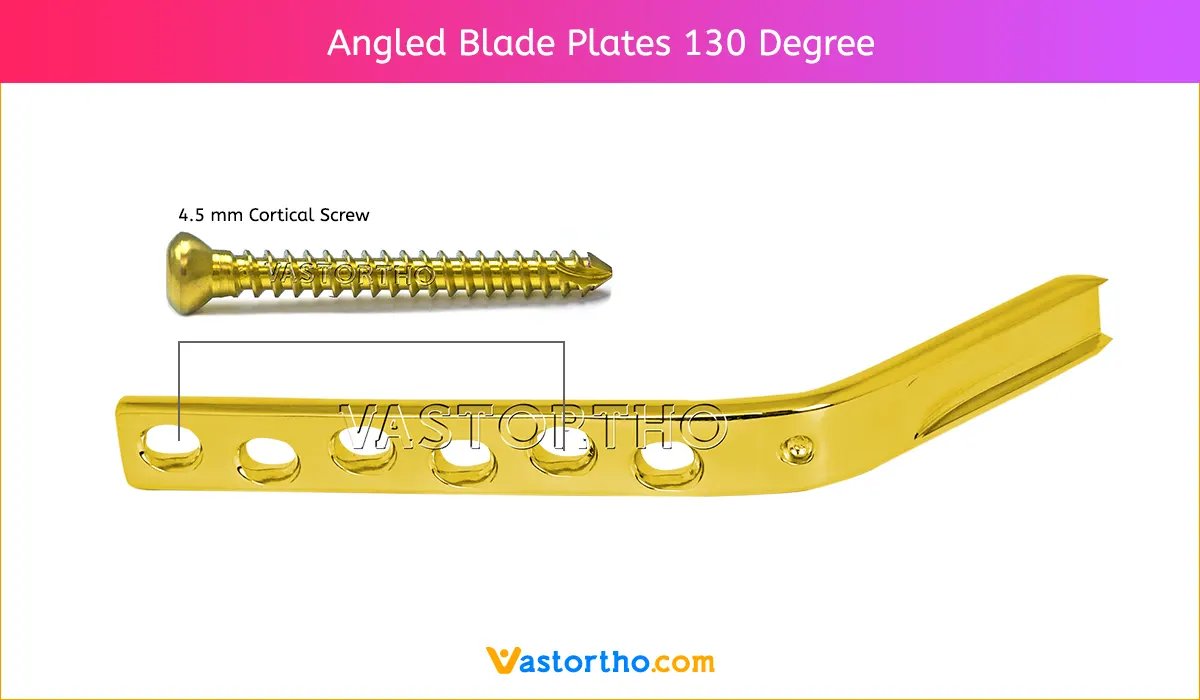

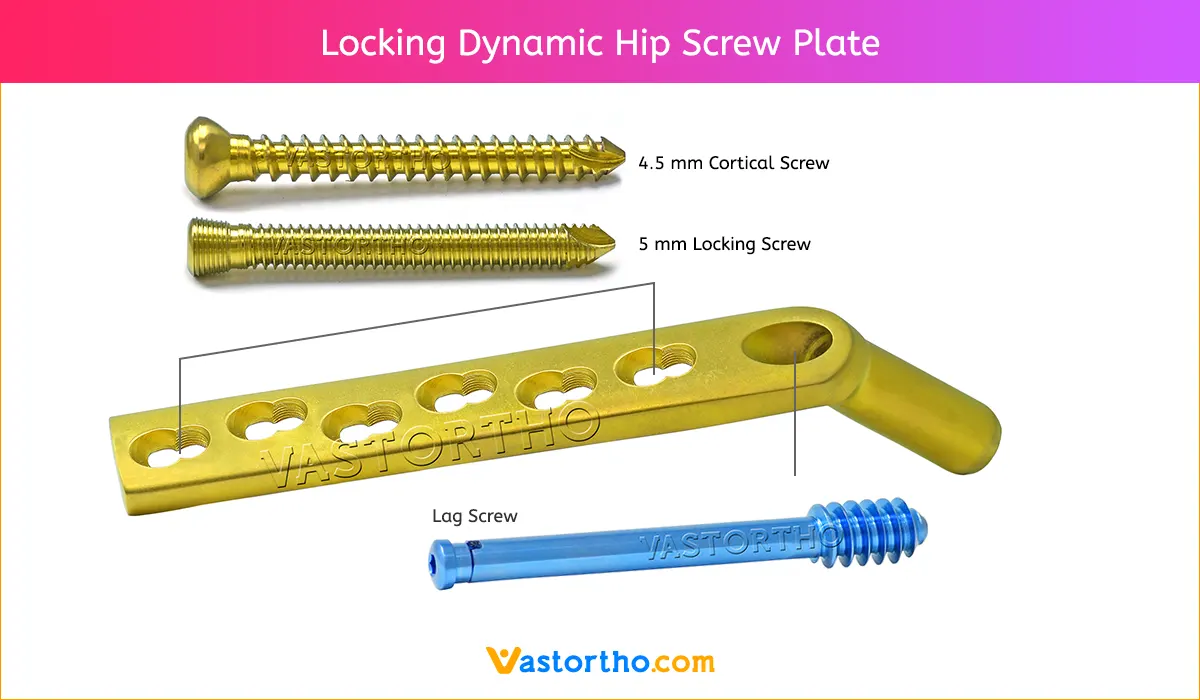

Fix the plate shaft to the bone with a 4.5 mm cortex screw.

Note: If axial compression is desired, first use the articulated tension device (ATD). Hook the opened device into the most proximal plate hole and fix to the bone with a short cortex screw. Tighten the bolt of the device to obtain the necessary compression. Insert additional 4.5 mm screws. Remove the ATD to insert the last two 4.5 mm cortex screws. Perform final tightening of screws.